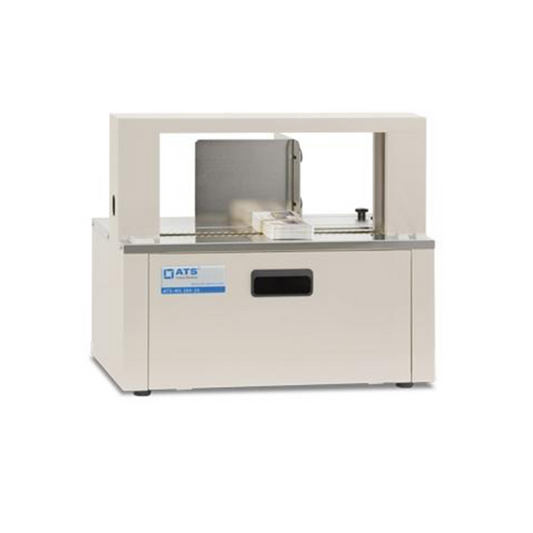

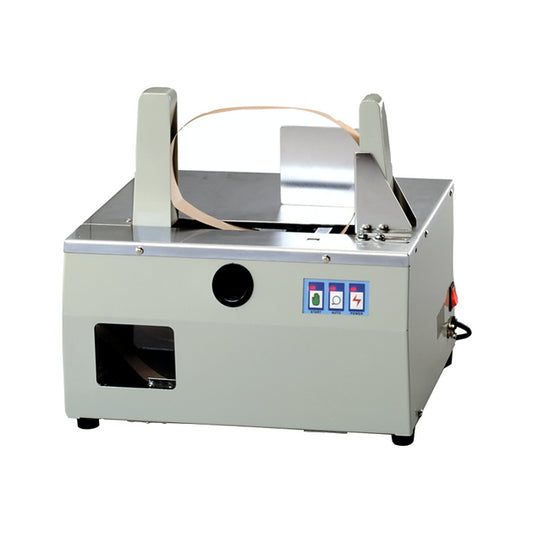

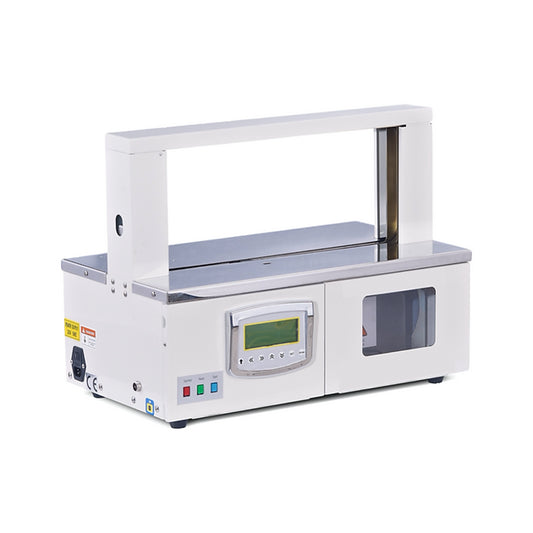

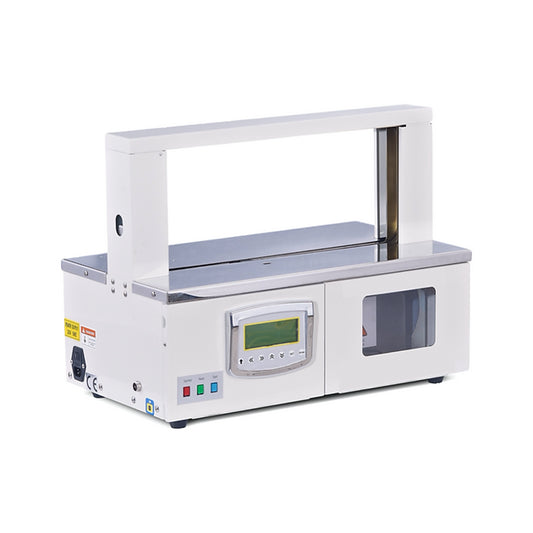

Collection: Banding Machines

Banding Machines

There are many types of banding machines, bundling machines, and strapping machines. Some of the machines below are special to one type, but others can be reconfigured to handle many different types of banding material. These machines will wrap some sort of band or binding material around a handful of products to keep them together. Banding is a very popular method of selling products in easy-to-handle batches or bundles. It's simple convenience and everyone loves receiving a clean bundle of products.

The most elite form of bundling is banding. Banding is used to showcase products and protect delicate, high-end materials. Banding is an alternative to strapping adhesive labeling and chipboard sleeving. Banding uses wide but thin material to keep a strong hold on products without causing damage. Bands are available in bleached white or unbleached paper. The unbleached paper bands look similar in color to a corrugated box. The ends of the band are usually sealed together with an ultrasonic weld. The ultrasonic weld is very fast and doesn't leave any kind of mess.

Additional benefits include:

- Easy removal without tools

- Live, inline printing

- Vibrant, stunning graphics on pre-printed material

- Large selection of material and machine options

Whether you're just getting started with banding or need a robust system for advanced packaging line, we have banding systems from table-top to fully automated to accommodate your applications.

Sold out

Sold out