Standard Horizon

Horizon BQ-470 Automatic Perfect Binder

Horizon BQ-470 Automatic Perfect Binder

This Product is Discontinued

This Product is Discontinued

Browse our collections to find a modern replacement or simply reach out to our sales team.

This model has been discontinued. Check out the Horizon BQ-500 Perfect Binder

Standard Horizon Perfect Binders feature cutting edge automation that lets you set up via a user-friendly color touch screen control panel. Tight manufacturing tolerances, precise cover feed systems and powerful nipping jaws combine to produce strong square binds, reliable performance and a long trouble-free machine life.

Horizon BQ-470 4-Clamp Automatic Perfect Binder

The 4-clamp Horizon BQ-470 Automatic Perfect Binder dramatically increases productivity with fully automated set-up. It can bind up to 2.5″ thick books at speeds up to 1,350 books per hour. Quick-change interchangeable glue tanks allow switching between EVA and PUR adhesive in mere minutes. Maximum glue penetration and a superior side glue application system ensure a high quality look and strong, square binds on every book the BQ-470 makes.

Horizon BQ-470 Manuals and Resources

| Filename | Description | Filetype | Size | Download Link |

|---|---|---|---|---|

| BQ-470 Glue Temperature Guide | 191 KB | 191 KB | Download | |

| BQ-470 Parts Manual Volume 10 | 39,711 KB | 39,711 KB | Download | |

| BQ-470 Operator Manual | 31,230 KB | 31,230 KB | Download |

Horizon BQ-470 Automatic Perfect Binder Details

- Huge Clamp Opening for Easy Book Block Feeding

- Automatic Milling Width Adjustment

- Automatic Side Gluing Roller Width

- Automatic Glue Length (Top-Bottom) at glue tank unit

- Auto Wiper Opening for Glue Amount (First Application Roller/Second Application Roller) at glue tank unit

- Auto Spine Glue Thickness (Second Application Roller Height) at glue tank unit

- Auto Nipping Width at nipping section

- Auto Guide Width (Fore-edge) at cover registration section

- Auto Cover Tail Edge Positioner at cover registration section

- Preset Scoring Position (4 lines) at scoring section

- Automatic Guide Width at cover feeding section

- Automatic Guide Width at book delivery section

Horizon BQ-470 Book Binding Glue PUR or EVA

The BQ-470 incorporates the remarkable PUR binding mechanism and features an interchangeable glue tank, for both EVA and PUR adhesives. Operators can swap out the tank to switch between EVA or PUR. There's a manual milling adjustment on the front of the machine to change the milling settings for better glue adhesion.

- PUR - Polyurethane reactive adhesive suitable for coated stock. Lay-flat binding can be performed.

- EVA - Commonly used for all kinds of binding. The hot-melted glue can be used repeatedly so there's no need to clean up the tank after operation.

Strong, Environmentally Friendly PUR Solution

Polyurethane Reactive, also called PUR, is a polyurethane adhesive attracting attention for binding strength and eco-friendliness.

- Strong and Lay Flat Binding - As the printing industry diversifies, there is growing demand for binding with color sheets. EVA hotmelt glue has difficulty binding coated stock firmly, and does not currently enable acceptable lay-flat binding. However, PUR hotmelt glue can provide adequate binding strength and lay-flat quality for both offset and digital prints.

- Durable Against Temperature - PUR hotmelt glue retains durability and flexibility in both high and low temperatures. The temperature resistance for PUR hotmelt glue ranges from –20 to 120 degrees Celsius versus 0 to 60 degrees Celsius for EVA hotmelt glue. This allows PUR bound books to be handled in almost any climate or location.

- Ecology - PUR adhesive is environmentally friendly, allowing PUR-bound books to be recycled. PUR also has a lower melting point (120 degrees celsius) than EVA for operational energy savings

- Fully Automated

- EVA Hotmelt

- PUR Hotmelt

- Book-Binding Up to 65 mm (2.55") Thickness

- Ergonomic Sliding Windows

- Color Touch Screen

- Milling Lever

- Nipping Height Adjustment

- Suction Cover Feed

- Supersonic Double Feed Detector Sensor

- Delivery Conveyor

- Smoke Extractor

- Scoring Section Cover Feeding Section

- Cover Registration Section

- Glue Tank Unit

- One To One Book Production

Horizon BQ-470 Automatic Perfect Binder Specifications:

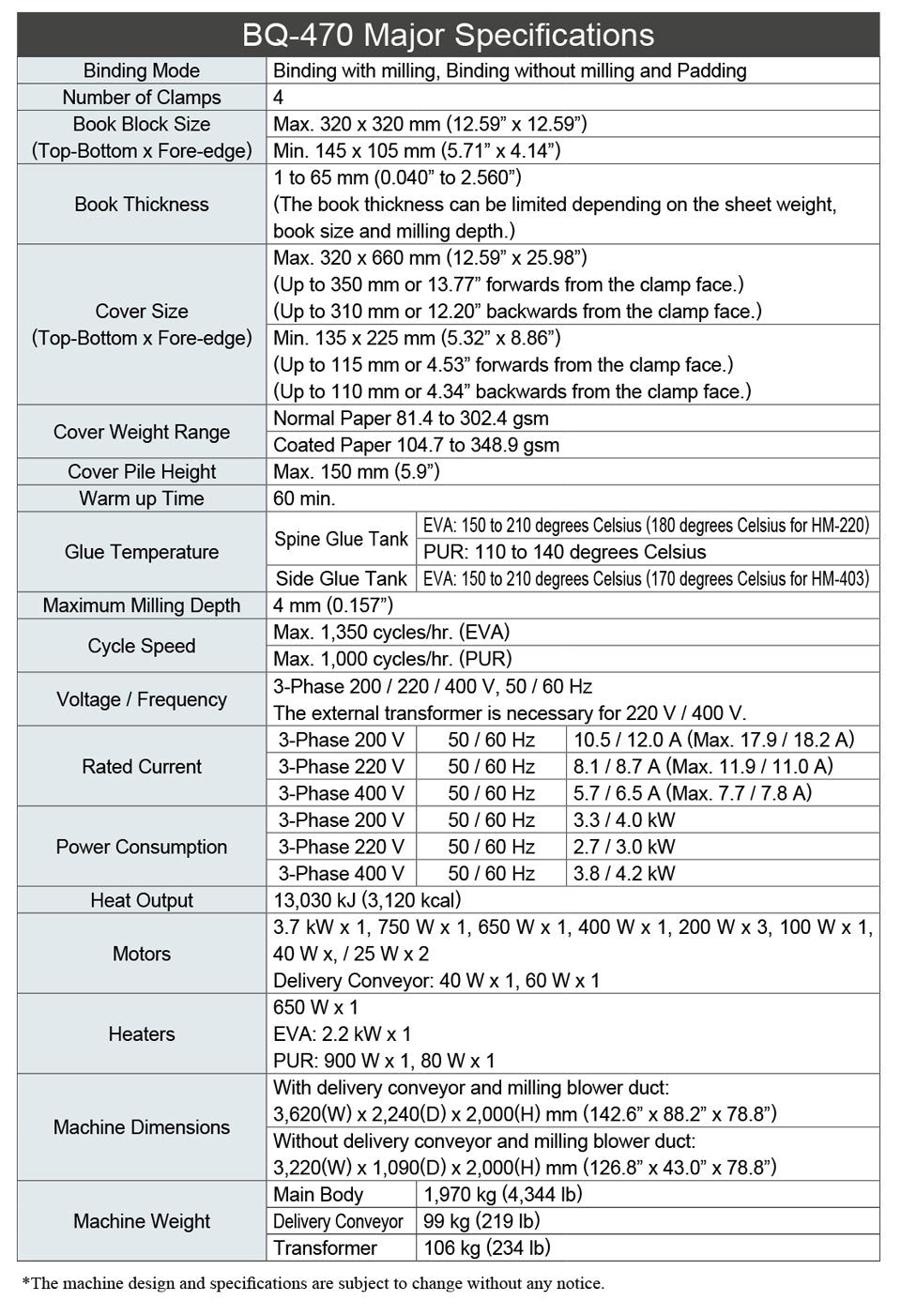

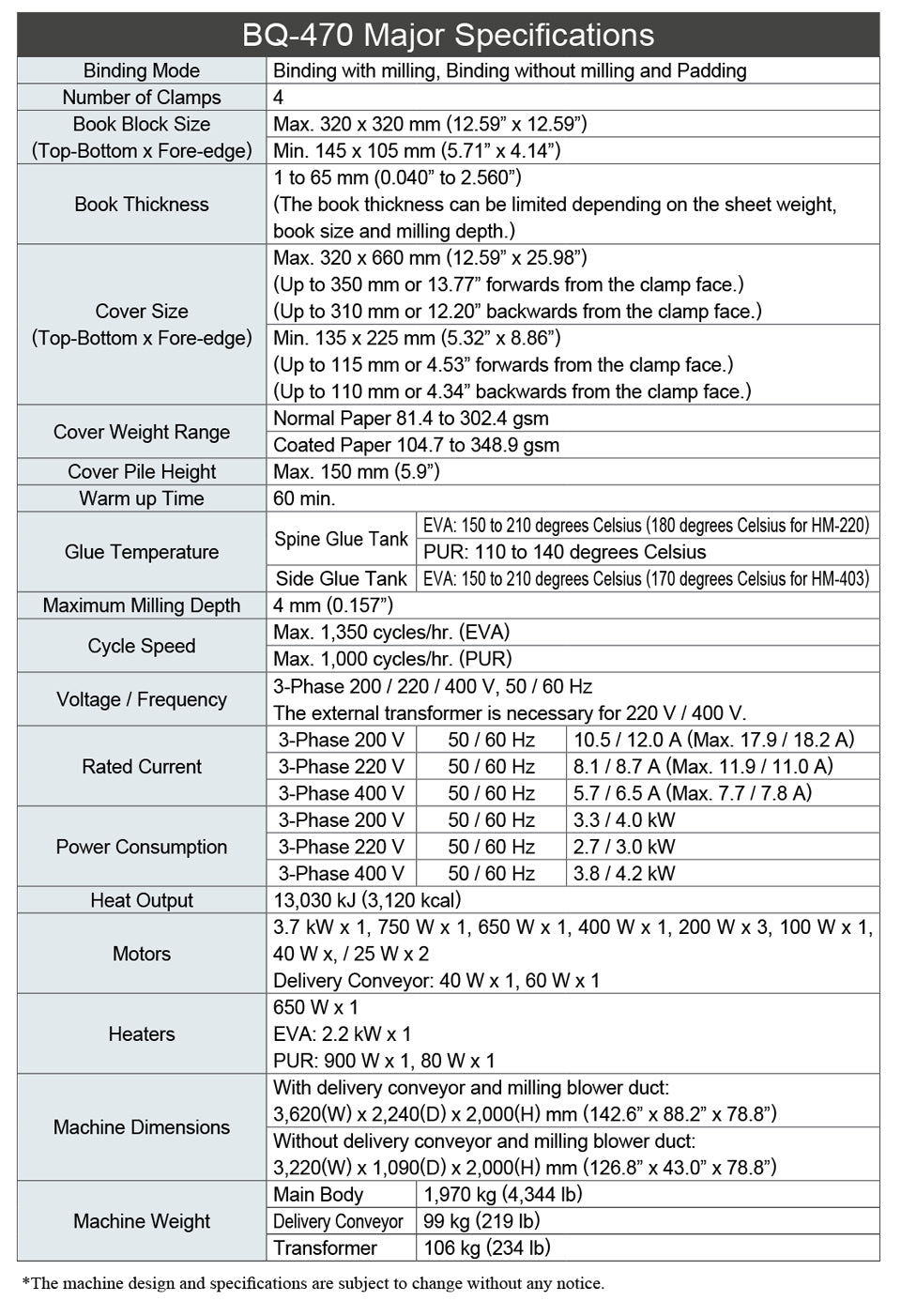

| Binding Mode | Binding with milling, Binding without milling and Padding | ||

| Number of Clamps | 4 | ||

| Book Block Size (Top-Bottom x Fore-edge) |

Max. 320 x 320 mm (12.59” x 12.59”) | ||

| Min. 145 x 105 mm (5.71” x 4.14”) | |||

| Book Thickness | 1 to 65 mm (0.040” to 2.560”) | ||

| The book thickness can be limited depending on the sheet weight, book size and milling depth. | |||

| Cover Size (Top-Bottom x Fore-edge) |

Max. 320 x 660 mm (12.59” x 25.98”) | ||

| Up to 350 mm or 13.77” forwards from the clamp face. | |||

| Up to 310 mm or 12.20” backwards from the clamp face. | |||

| Min. 135 x 225 mm (5.32” x 8.86”) |

|||

| Up to 115 mm or 4.53” forwards from the clamp face. | |||

| Up to 110 mm or 4.34” backwards from the clamp face. | |||

| Cover Weight Range | Normal Paper 81.4 to 302.4 gsm | ||

| Coated Paper 104.7 to 348.9 gsm | |||

| Cover Pile Height | Max. 150 mm (5.9”) | ||

| Warm Up Time | 60 min. | ||

| Glue Temperature | Spine Glue Tank | EVA: 150 to 210 degrees Celsius (180 degrees Celsius for HM-220) | |

| PUR: 110 to 140 degrees Celsius | |||

| Side Glue Tank | EVA: 150 to 210 degrees Celsius (170 degrees Celsius for HM-403) | ||

| Max. Milling Depth | 4 mm (0.157") | ||

| Cycle Speed | Max. 1,350 cycles/hr. (EVA) | ||

| Max. 1,000 cycles/hr. (PUR) | |||

| Voltage Frequency | 3-Phase 200 / 220 / 400 V, 50 / 60 Hz | ||

| The external transformer is necessary for 220 V / 400 V. | |||

| Heat Ouptut | 13,030 kJ (3,120 kcal) | ||

| Rated Current | 3-Phase 200 V | 50 / 60 Hz | 10.5 / 12.0 A (Max. 17.9 / 18.2 A) |

| 3-Phase 220 V | 50 / 60 Hz | 8.1 / 8.7 A (Max. 11.9 / 11.0 A) | |

| 3-Phase 400 V | 50 / 60 Hz | 5.7 / 6.5 A (Max. 7.7 / 7.8 A) | |

| Power Consumption | 3-Phase 200 V | 50 / 60 Hz | 3.3 / 4.0 kW |

| 3-Phase 220 V | 50 / 60 Hz | 2.7 / 3.0 kW | |

| 3-Phase 400 V | 50 / 60 Hz | 3.8 / 4.2 kW | |