-

AccurioJet KM-1 Digital Press | High-Quality Color Printing Solution

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per$0.00 USDSale price $0.00 USD -

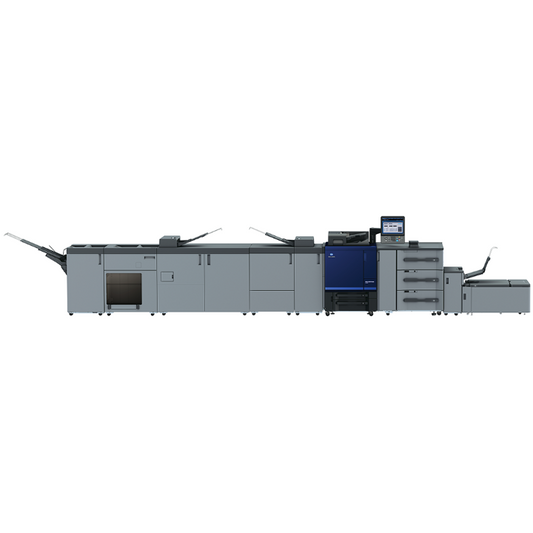

Konica Minolta AccurioPress C7100 Digital Press

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per -

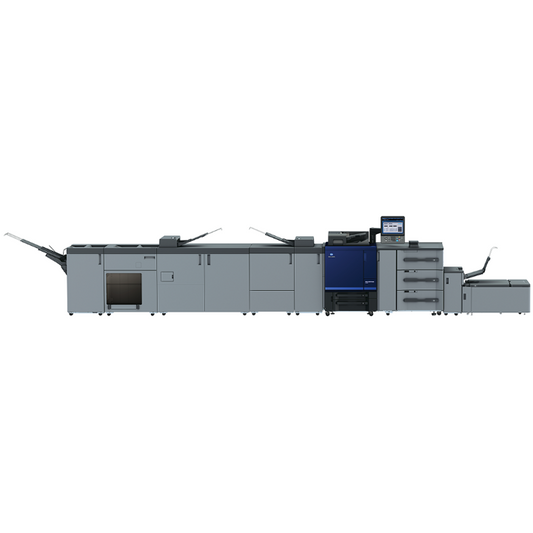

Konica Minolta AccurioPress C6100 Digital Color Press | High-Quality Production Printing

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per$0.00 USDSale price $0.00 USD -

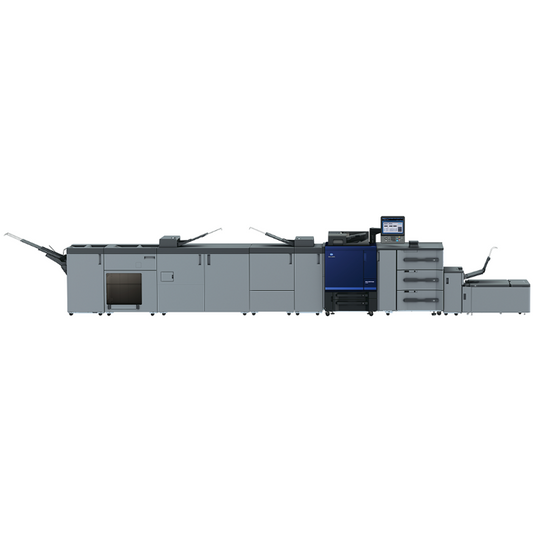

AccurioPress C6085 Digital Color Press

Vendor:Konica MinoltaRegular price $58,500.00 USDRegular priceUnit price per$0.00 USDSale price $58,500.00 USD -

Konica Minolta AccurioPress C4070 Digital Press

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per -

AccurioPress C3070 Digital Press

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per$0.00 USDSale price $0.00 USD -

Konica Minolta AccurioPress C2070 - Demo Model

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per$0.00 USDSale price $0.00 USD -

Konica Minolta bizhub C654e

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per$0.00 USDSale price $0.00 USD -

Konica Minolta bizhub Press 2250P for Black and White Digital Printing

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per$0.00 USDSale price $0.00 USD -

Cyan Toner - Meteor 8700XL 5908 - OEM Original Chipped MGI Toner for DP8700S & DP8700XL

Vendor:Konica MinoltaRegular price $112.31 USDRegular priceUnit price per$0.00 USDSale price $112.31 USD -

OEM Original Chipped MGI Magenta Toner 5907 for DP8700S & DP8700XL

Vendor:Konica MinoltaRegular price $112.31 USDRegular priceUnit price per$0.00 USDSale price $112.31 USD -

MGI DP8700 series Charging Corona 5910

Vendor:Konica MinoltaRegular price $51.00 USDRegular priceUnit price per$0.00 USDSale price $51.00 USD -

MGI OPC Drum 5909

Vendor:Konica MinoltaRegular price $361.60 USDRegular priceUnit price per$0.00 USDSale price $361.60 USD -

MGI DP8700 Charging Corona 5910 for Enhanced Printing Performance

Vendor:Konica MinoltaRegular price $51.00 USDRegular priceUnit price per$0.00 USDSale price $51.00 USD -

AccurioPress C4080 Digital Press

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per -

Konica Minolta AccurioLabel 400 Press

Vendor:Konica MinoltaRegular price $0.00 USDRegular priceUnit price per -

Konica Minolta TN629C Cyan Toner (AD3H430)

Vendor:Konica MinoltaRegular price $125.78 USDRegular priceUnit price per -

Konica Minolta TN629K Black Toner AD3H130

Vendor:Konica MinoltaRegular price $89.81 USDRegular priceUnit price per -

Konica Minolta TN629M Magenta Toner (AD3H330)

Vendor:Konica MinoltaRegular price $115.83 USDRegular priceUnit price per -

Konica Minolta TN-629Y Yellow Toner Cartridge (AD3H230)

Vendor:Konica MinoltaRegular price $137.15 USDRegular priceUnit price per -

Konica Minolta DR620 Color Drum Unit (ACE60Y1)

Vendor:Konica MinoltaRegular price $398.95 USDRegular priceUnit price per -

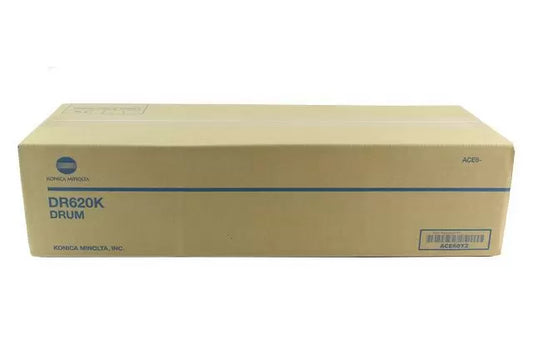

Konica Minolta DR620K Black Drum Unit (ACE60Y2)

Vendor:Konica MinoltaRegular price $398.95 USDRegular priceUnit price per -

Konica Minolta A5WH0Y0 Drum Unit (DU-105)

Vendor:Konica MinoltaRegular price $379.00 USDRegular priceUnit price per -

Konica Minolta DV-614C Cyan Developer (A3VX900)

Vendor:Konica MinoltaRegular price $499.00 USDRegular priceUnit price per

Konica Minolta Printing Systems

Konica Minolta Printing Systems